Welding may appear simple when you watch someone do it. However, to be a great welder, it takes practice, coordination, and attention to detail. Welds are pretty easy to mess up, and the mark of a great welder is not only the products they produce, but also the smoothness of their weld.

Welding, like most careers, has a language all its own, and if you are talking to a welder and you are outside the welding world, it can be confusing. The Missouri Welding Institute in Nevada, Missouri, is a welding trade school that offers various welding certificates to launch your welding career. Welding is in high demand due to the fact most people opt for a desk job over a trades job. Plus, welding is highly satisfying, as you make beautiful creations out of virtually nothing. Below, we’ll offer up more common welding terms that you should know. Contact our welding school today for enrollment information!

More common welding terms you should know

Gas Carbon-Arc Welding

Gas carbon-arc welding is a type of weld that uses a carbon electrode and an electrical arc to weld your metal together. Argon and helium gas are popular gases that are used to shield your weld. Shielding gases are sent through the welding instrument, or gun, itself to protect the weld pool from contamination, which can weaken your weld.

Gas Metal-Arc Welding

Also known as Metal-Inert-Gas (MIG) welding, this type of weld uses the heat from the arc the metal electrode produces to fuse your metals together. Like in gas carbon-arc welding, gases are used as shields. Helium is a popular choice.

Plasma Arc Welding

A type of welding that uses a constricted arc. You can choose between a non-consumable electrode and the weld pool or between a regular, consumable electrode and a constricting nozzle. Ionized gas is produced that then serves as the shield.

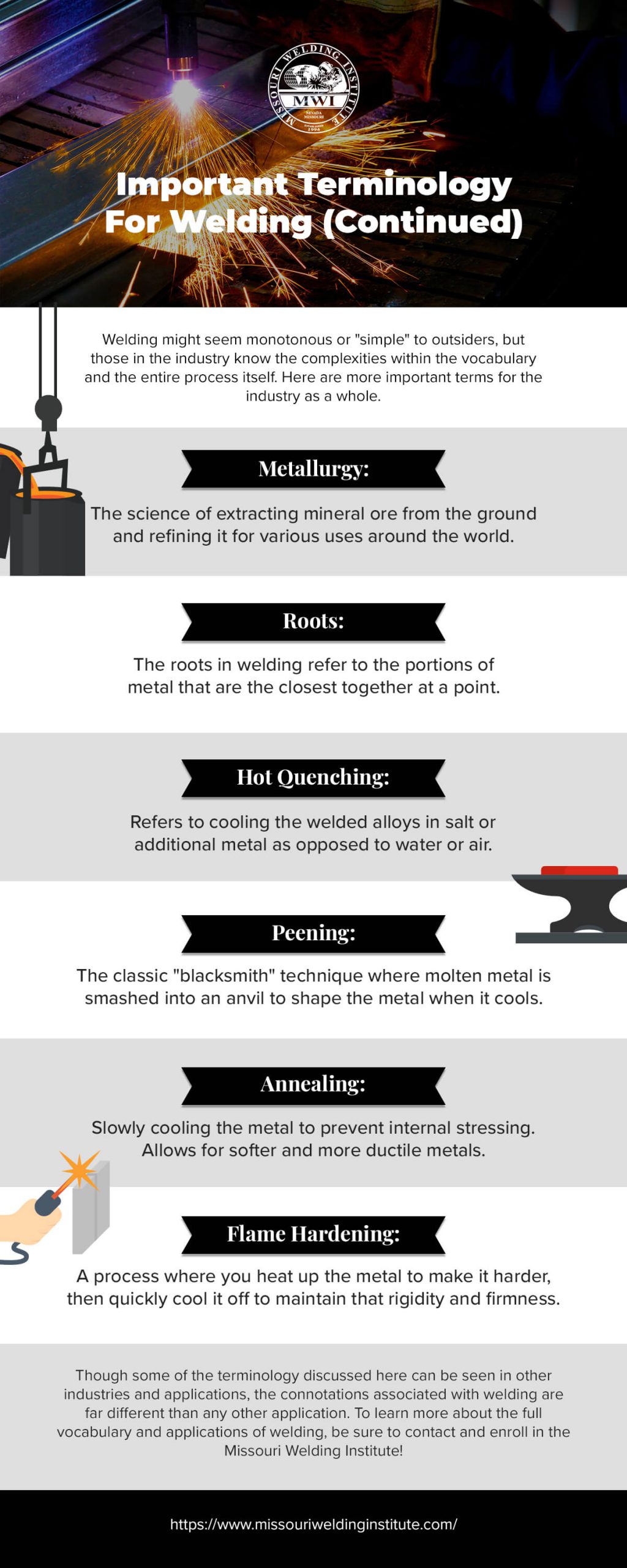

Roots

There are roots of joints and roots of welds. A root of the joint is the part where the two metals that have been welded together are the closest, which is usually a point, but it could also be a line. The root of the weld is the point where the weld fuses to the base metal.

Hot Quenching

This cool term refers to when heated metal or alloys are cooled in molten metal or salt instead of using water or air to cool. When quenching is used alone, it refers to any process of the cooling of your metal after the weld.

Flame Softening and Hardening

Flame softening is the process where you make your metal soft by heating it and then letting it cool down slowly. This process has been around for thousands of years. Flame hardening is when you use heat to make a metal hard, which is followed by a quick cooling off period (known as quick quench), rather than a slow cooling off period.

Metallurgy

Metallurgy is the science of extracting mineral ore from the ground, refining them, and then preparing them for various uses around the world. Metallurgy also involves the study of the property of the metals, which helps welders decide which type of metal and/or alloy to use in their productions.

Peening

Peening is what you will see blacksmiths doing in all of the old TV shows and movies. It’s the working of metal by pounding it with a hammer on an anvil. This is done to relieve stress, reduce distortion, and reduce cracking. Peening can reduce the ductility of a metal, as well as its impact properties, which restricts its use to non-heavy duty jobs. Peening can improve the fatigue resistance of metal as well.

Weld Distortions

Weld distortions are caused by the actual weld process itself. When metal is heated and then cools, it can distort. This is caused by the physical and the mechanical properties of the metal that is used. When you are welding, the arc increases the temperature of the metal near it. This can decrease the elasticity of the metal, as well as its conducting capacity. All of this affects heat flow and the uniformity of the heat across the weld area. This, ultimately, affects the weld itself, which is what matters.

Annealing

Annealing is the word given to the welding process of slowly cooling the metal so that minimal internal stresses occur. The metal will be softer and more ductile as well. This is a very controlled process, as it has to be precise to work. Annealing is used when you do want a softer metal, to improve its machinability, and to enhance its electrical conductivity. Annealing also allows for cold working to take place without the risk of cracking. Steel is most often used in annealing, as well as copper, aluminum, and brass. Cold working is where metal is welded together without the use of heat.

Flames

Flames are a big part of the welding process. Flame cutting, or oxygen cutting, uses the properties of the element oxygen to help cut base metals at high temperatures. Flame gouging, or oxygen gouging, uses oxygen to help create grooves in surfaces. Flame hardening is a process to create a hard metal that is used in tandem with a quick quench and a flame. Flame softening is a process that softens metal and then allows it to cool slowly.

Choose missouri welding institute in Nevada

Missouri Welding Institute in Nevada has built a reputation for producing some of the best graduates who are extremely well-prepared for a career in welding. In fact, we have a network of employers, both local and national, who are interested in hiring recent graduates with welding certificates from our welding school. Our job placement team has a proven track record of placing our graduates with employers they want to work for. With the emphasis on computers rather than on the trades, welders are in high demand. We also help you put together your resume, conduct job searches, and help you prepare for your job interviews. Our mission is for you to succeed, so we put a lot of time and resources into doing just that.

Our two tracks in our welding school are intense and designed to teach you everything you need to know as a beginning welder in the job market. Our Master Pipe Welding and Fitting Course and our Master Structural Welding and Fitting Course will help prepare you for a great career in the construction or manufacturing industries. We offer financial assistance for those that need it, and we partner with local apartment complexes in order to help you with housing needs. We also help our students who are veterans with all their employment and financial needs.

At Missouri Welding Institute in Nevada, you won’t find a more compassionate and caring staff. Our instructors have decades of experience working for a wide range of employers, and our front office staff is always ready to greet you with a warm smile and answer any administrative questions that you may have. We understand that moving here can be a challenge and maybe a bit scary as well. We’re here to make your transition to our welding school as smooth as possible. We invite you to visit us and see for yourself what we have to offer. Call us today!